ERP 5.0 Class Systems

There are many ERP systems available equipped with functions that support the core areas of a company’s operations, such as commerce, logistics, production, accounting or human resources and payroll. However, the correct operation of the main modules is not enough to gain a competitive advantage.

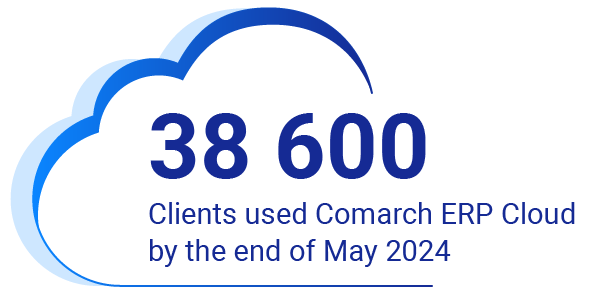

In order to enable our Clients to develop their business effectively, we have created ERP 5.0 solutions. In addition to the basic functionalities available in Comarch ERP systems, we offer over 20 integrating applications that address universal or industry-specific needs of enterprises of any size. This approach allows organizations to avoid additional integration and maintenance costs.

Read more about:

-

ERP 5.0 strategy

Over 20 applications integrating with the ERP system.

-

Comarch ERP systems

Tested and ready for new trends and challenges.

-

The role of AI

Everything about intelligent systems and applications for the companies.

-

Industry 5.0 and Cloud

Internet of Things (IoT) and Cloud in production plants.