Watch our video:

Reinventing Infrastructure Maintenance Within Field Services

Equipment maintenance planning in field service companies normally takes hours. All failures and changes result in unnecessary costs for you and your client. To manage maintenance challenges, you need data-driven field service software that helps you automate your work and optimize schedules, and which informs you about possible future failures.

Reduce repair-related costs, show your clients that you meet equipment maintenance agreements, and ensure their business continuity with our FSM software.

Do you want to learn more about the Comarch FSM solution? Order a free demo!

Watch our video:

Reinventing Infrastructure Maintenance Within Field Services

Some appliances can continue to operate even after a breakdown, in some cases thanks to the redundancy of their components, offering limited efficiency.

With a field service maintenance module, you can gather all monitoring data and compare this information in its own right or with desired values. Deviations can be automatically detected and reported as new maintenance tasks, thus saving time and money by preventing failure in more expensive hardware protected by the damaged equipment.

To avoid unexpected breakdowns and associated downtime and costs in field service companies, equipment requires replacement parts and periodical inspections.

With data about recommended inspection dates and a preventive maintenance module, you can automatically plan service appointments and avoid expensive repairs. By assigning tasks at the right time and preventing breakdowns, you can also extend the life of assets, increase efficiency, and ensure uninterrupted productivity. As a result, you benefit from reduced maintenance costs and save time spent on planning schedules for technicians.

Comarch FSM enables even more proactive issue resolution, before the real problem occurs. The built-in AI/ML maintenance engine supported with historical data and information collected in real time can trigger actions to prevent potential issues.

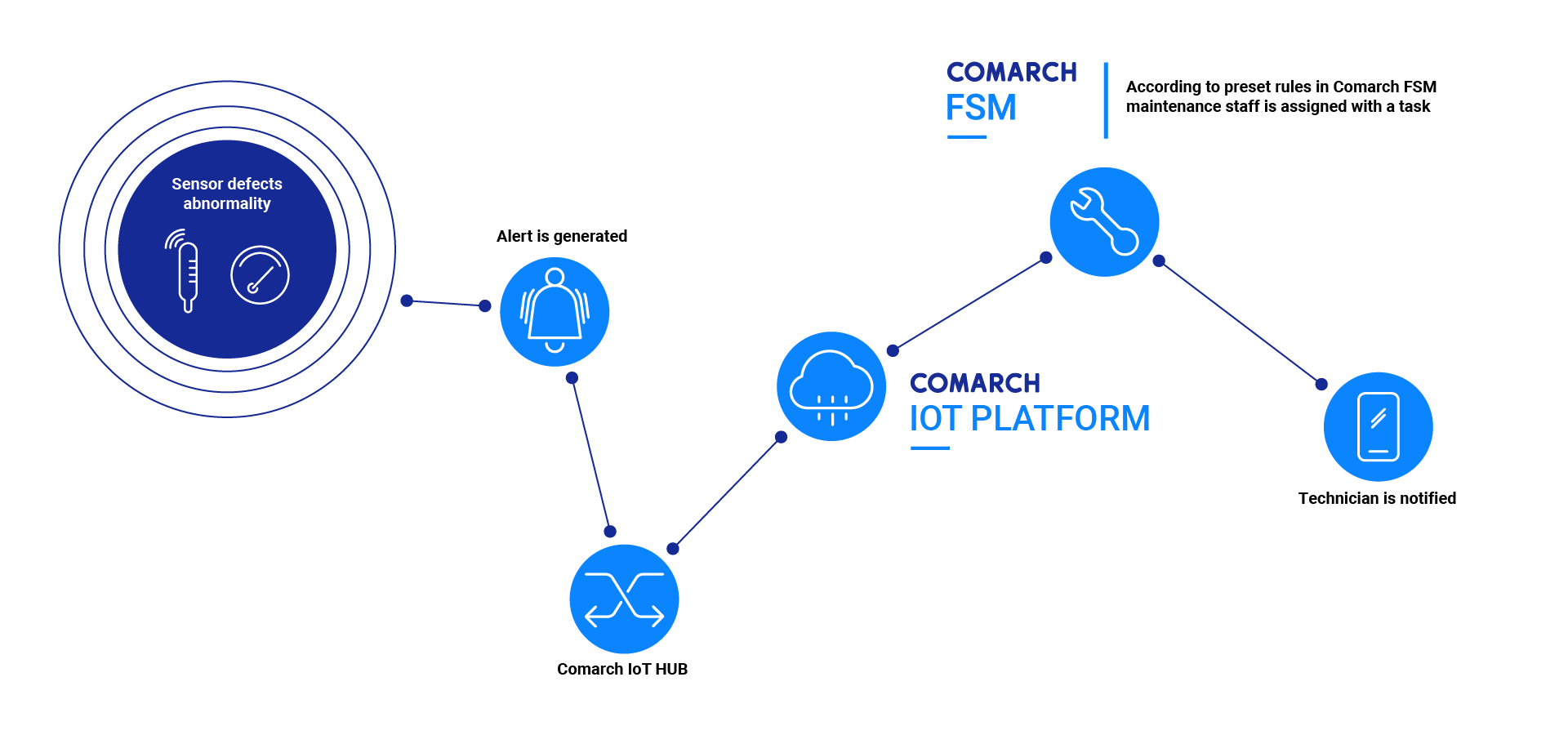

Additionally, your assets can be retrofitted with IoT sensors to monitor different parameters (i.e. liquid, temperature, weather, dust, humidity levels, predict and eliminate the risk of equipment malfunction or shortage of material.

As data processing takes place in real time, technicians can receive notifications on mobile devices about problems and react immediately, so business operations may continue uninterrupted, the cost of repairs can be minimized, and new equipment purchases may become unnecessary.

Please wait

Tell us about your business needs. We will find the perfect product for your challenge.